-

鹤管潜液泵

-

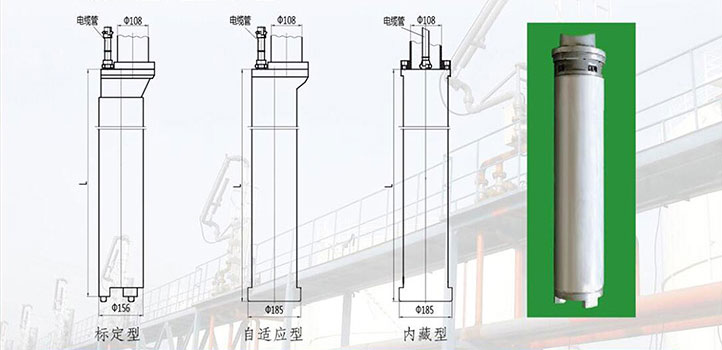

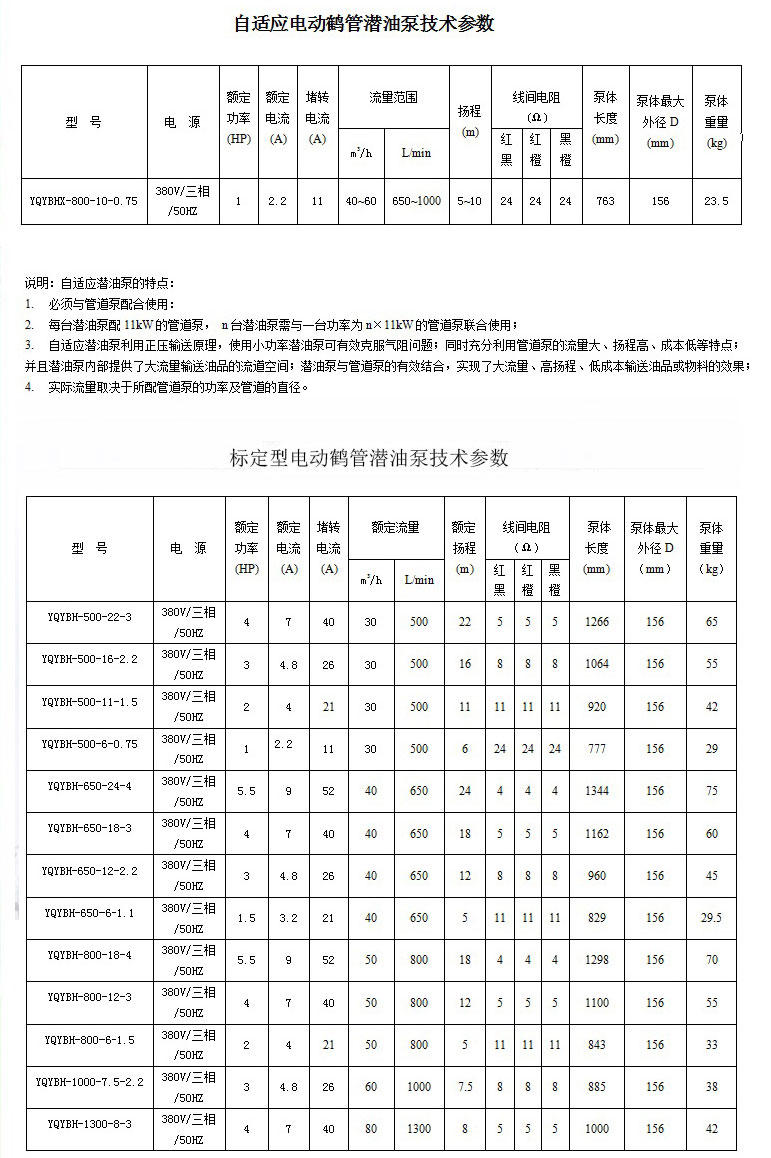

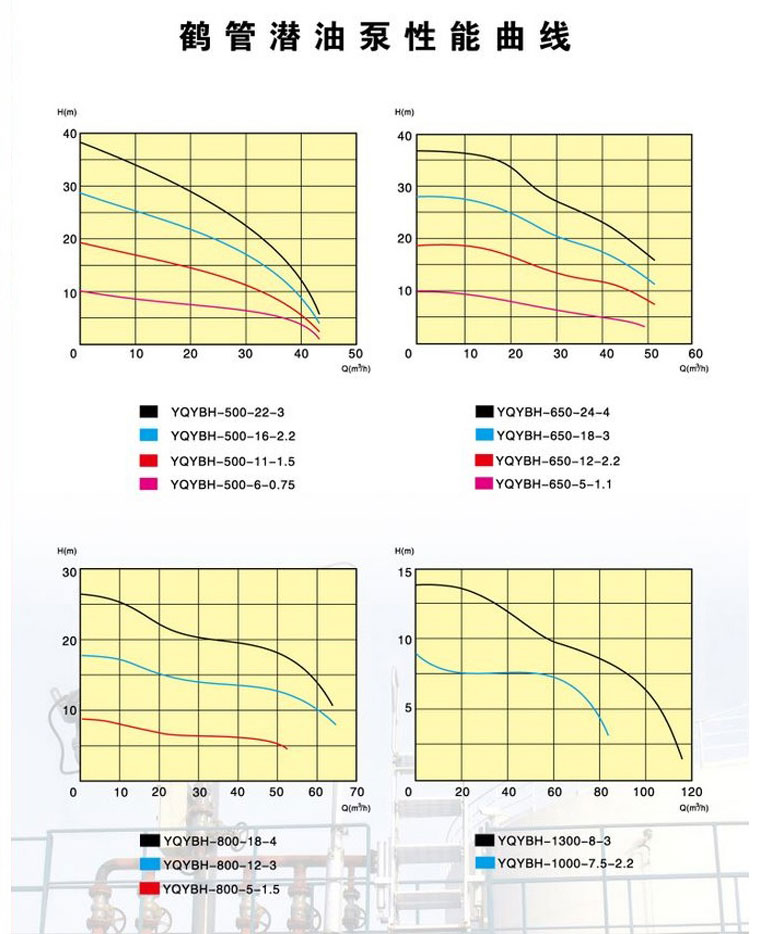

电动鹤管潜油泵安装方便简单易用当铁路槽车停放到位后,工人放下电动鹤管潜油泵,接好静电接地;按预先设定收油方案,打开相应阀门、电动鹤管潜油泵、管道泵,开始卸油;当卸油至槽车低液位时潜油泵内油压达不到设定值,潜油泵将自动停止工作,关闭相应阀门,打开泵棚扫仓滑片泵及阀门,通过电动潜油泵内内置的扫仓管进行扫仓;扫仓管扫仓完毕,关闭相应阀门、管道泵、扫仓泵,撤出静电接地夹,提起鹤管,卸油作业完毕使用时收油鹤管和扫仓管一次到位,改变了以往先鹤管卸油后扫仓管抽底的传统卸油模式,减少了重复操作,节省了卸油时间,有效的减轻工作人员的工作强度。节能高效优化环境YQYBH系列防爆鹤管潜油泵由于其叶轮浸没在介质中,相比于其他结构泵,卸油时不必自吸,其进口也不存在吸空现象,因此,泵在输送介质时,变吸为送,介质不会汽化,泵不易发生汽蚀、系统不会发生气阻现象。彻底解决了高温炎热天气下卸油、输油时的问题,实现全天候卸油。YQYBH系列电动鹤管潜油泵功能齐全装卸两用YQYBH系列电动鹤管潜油泵除了增加了内置扫仓管,无需提泵扫仓之外的功能以外还增加了装卸油用的功能。老型号电动鹤管潜油泵为220V电压,泵严格禁止反转,而新型号电动鹤管潜油泵为380V电压,可以反转。此时铝垂管下端的潜油泵作为流道,实现发油的目的。

Technical Datasheet for Green Brand Submersible Pump Model Voltage/Phase/

FrequencyRated Power Rated Current Locked Rotor Current Rated Flow Rated Head Pump Length (HP) (A) (A) (L/min) (m) (mm) Standard One-Phase Submersible Pump YQYBD-100-15-0.75 220/1Ph/50HZ 1 5.5 20 100 15 502 YQYBD-160-20-1.1 220/1Ph/50HZ 1.5 8 27 160 20 578 YQYBD-180-20-1.5 220/1Ph/50HZ 1.5 8 27 180 20 603 Standard Three-Phase Submersible Pump YQYB-100-15-0.75 380/3Ph/50HZ 1 2.2 11 100 15 492 YQYB-160-20-1.1 380/3Ph/50HZ 1.5 3.2 21 160 20 578 YQYB-180-20-1.5 380/3Ph/50HZ 2 4 21 180 20 603 YQYB-200-24-1.5 380/3Ph/50HZ 2 4 21 200 24 630 High-lift Submersible Pump YQYB-180-35-2.2 380/3Ph/50HZ 3 4.8 26 180 35 944 YQYB-180-45-3 380/3Ph/50HZ 4 7 40 180 45 1131 YQYB-180-74-4 380/3Ph/50HZ 5.5 9 52 180 74 1336 YQYB-200-30-2.2 380/3Ph/50HZ 3 4.8 26 200 30 720 YQYB-200-41-3 380/3Ph/50HZ 4 7 40 200 41 1130 YQYB-200-52-4 380/3Ph/50HZ 5.5 9 52 200 52 1283 Large-flow Submersible Pump YQYB-500-5.5-0.75 380/3Ph/50HZ 1 2.2 11 500 5.5 690 YQYB-500-11-1.5 380/3Ph/50HZ 2 4 21 500 11 840 YQYB-500-16-2.2 380/3Ph/50HZ 3 4.8 26 500 16 980 YQYB-500-22-3 380/3Ph/50HZ 4 7 40 500 22 1200 YQYB-500-34-4 380/3Ph/50HZ 5.5 9 52 500 34 1220 YQYB-500-46-5.5 380/3Ph/50HZ 7.5 13 74 500 46 1520 YQYB-500-65-7.5 380/3Ph/50HZ 10 18 108 500 65 1850 Large-flow Submersible Pump YQYB-650-6-1.1 380/3Ph/50HZ 1.5 3.2 21 650 6 740 YQYB-650-12-2.2 380/3Ph/50HZ 3 4.8 26 650 12 890 YQYB-650-18-3 380/3Ph/50HZ 4 7 40 650 18 1100 YQYB-650-24-4 380/3Ph/50HZ 5.5 9 52 650 24 1040 YQYB-650-34-5.5 380/3Ph/50HZ 7.5 13 74 650 34 1330 YQYB-650-46-7.5 380/3Ph/50HZ 10 18 108 650 46 1570 Large-flow Submersible Pump YQYB-800-6-1.5 380/3Ph/50HZ 2 4 21 800 6 740 YQYB-800-12-3 380/3Ph/50HZ 4 7 40 800 12 1000 YQYB-800-18-4 380/3Ph/50HZ 5.5 9 52 800 18 970 YQYB-800-24-5.5 380/3Ph/50HZ 7.5 13 74 800 24 1190 YQYB-800-32-7.5 380/3Ph/50HZ 10 18 108 800 32 1350 YQYB-800-38-9.2 380/3Ph/50HZ 12.5 21 126 800 38 1460 Large-flow Submersible Pump YQYB-1000-6-2.2 380/3Ph/50HZ 3 4.8 26 1000 6 780 YQYB-1000-14-4 380/3Ph/50HZ 5.5 13 74 1000 14 870 YQYB-1000-21-6 380/3Ph/50HZ 8 14 83 1000 21 1090 YQYB-1000-28-7.5 380/3Ph/50HZ 10 18 108 1000 28 1248 YQYB-1000-35-9.2 380/3Ph/50HZ 12.5 21 126 1000 35 1380 YQYB-1000-42-11 380/3Ph/50HZ 15 25 150 1000 42 1570 Large-flow Submersible Pump+A75 YQYB-1300-7-3 380/3Ph/50HZ 4 7 40 1300 7 750 YQYB-1300-14-5.5 380/3Ph/50HZ 7.5 13 74 1300 14 970 YQYB-1300-21-9.2 380/3Ph/50HZ 12.5 21 126 1300 21 1120 YQYB-1300-28-11 380/3Ph/50HZ 15 25 150 1300 28 1300 YQYB-1300-35-15 380/3Ph/50HZ 20 34 204 1300 35 1500 Large-flow Submersible Pump YQYB-2100-17-9.2 380/3Ph/50HZ 12.5 21 126 1300 17 1200 YQYB-2100-27-15 380/3Ph/50HZ 20 34 204 1300 27 1510 Alcohols:

1-Pentanol 、Cyclohexanol、Sugar Alchohol、Benzyl alcohol、1,2-Propanediol、Ethylene glycol、1-Octanol、D(+)-2-Octanol、1-Butanol、DL-2-Octanol、Hexyl alcohol、3-Methyl-1-butanol、Mixed isoamyl alcohol、Waste ethanol、Diethylene glycol、4-Hydroxy-4-methyl-2-pentanone、Isopropanol、2-Methyl-1-propanol、Methanol、Ethanol、Mixed methanol& ethanol、1-Propanol

Benzene Series:

Motor benzol、Aromatic Solvent Oil 100# 、Toluene、Aromatic Solvent Oil 150#、Fluorobenzene、1,2-Dimethylbenzene、Nitrobenzene、Trimethylbenzene、Mesitylene、Xylene、4-Fluorotoluene、1,4-Dimethylbenzene、Heavy aromatics、Trimethylbenzene (S100)

Ethers:

Petroleum ether、1-Methoxy-2-propanol、Tetrahydrofuran、tert-Butyl methyl ether、2-Ethoxyethanol、2-Methoxyethanol 99%、2-Butoxyethanol、Butyldiglycol

Alkanes:

Morpholine、Epichlorohydrin、Heptane、Methylcyclohexane、Hexane、Cyclohexane 99.5%、Dichloromethane、1,2-Dichloropropane、1,2-Dichloroethane、Diethoxymethane

Organic Acid:

Butyric acid、Acetic acid glacial、Isobutyric acid、Methacrylic acid、Acrylic acid、Acetic acid glacial 36%、Acetic acid glacial 99% 、Cyclohexanecarboxylic acid

Ketones:

2-Butanone、Cyclohexanone、Acetone

Amines & Nitriles:

Aniline、Ethanolamine、Acetonitrile、Diesel Exhaust Fluid、Acrylonitrile、Formamide、Waste Acetonitrile、2-Chloroacrylonitrile、Isopropylamine、N,N-Dimethylformamide、Methylamine、2,3-Dimethylaniline、Triethylamine、2,6-Diisopropylaniline、Cyclohexylamine、Dimethylamine

Aldehydes& Alkenes:

Formaldehyde Solution、Dimethoxymethane、Allyl chloride、Sulfurized isobutylene、Styrene、1,1-Dichloroethylene 99.9%

Oil and Fuel:

Diesel、gasoline、kerosene、Turpentine oil、Solvent-extracted oil #6、Solvent-extracted oil #120、Solvent-extracted oil #200、Wastewater with Turpentine oil、Solvent-extracted oil #1000

Lipid:

gamma-Butyrolactone、Methyl acetate、Ethyl acetate、Propyl acetate、Butyl acetate、DBE、Methyl propionate、Ethyl propionate、Propyl propionate、Methyl oleate、Ethyl butyrate、Methyl salicylate、Dimethyl carbonate、tert-Butyl acetate、Propyl acetate、Ethyl formate 99%、Ethyl acrylate、Methyl acrylate、Methyl cyanoacetate、2-Propenoic acid, isooctyl ester、Methyl acetoacetate、Dimethyl malonate、Dimethyl sulfate、Isopropyl acetate、Butyl acrylate、2-Butoxyethyl acetate、DL-sec-Butyl acetate、2-Acetylbutyrolactone、2-Ethoxyethyl acetate、1-Methoxy-2-propyl acetate、Tetrahydrofuran& Ethyl acetate、Vinyl acetate

Others:

Wastewater、Urea、Pyridine、Phenylmercury acetate、Hydrazine hydrate、Thionyl chloride、1,3-DioxolaneInstallation Instruction

1、Lift the pump with a crane, and put it gently into the hole on the manhole cover. Confirm the best installation position by angle adjustment.

2、Weld the riser and flange to the manhole cover.Installation Sequence

1、The thickness of the manhole cover should be greater than or equal to 20mm.

2、A level gauge must be set and interlocked with the ESP. Otherwise, as the liquid level is too low, the cooling system would fail. The motor would be damaged with the high temperature rise.

3、A motor protector should be installed in the control box.

In China, more than 10,000 sets of Green Brand Submersible Pump were widely installed in petroleum stations, highway service areas, railway, oil depots, airports, railway trestles, piers, chemical factories, pharmaceutical factories, diesel power stations, backup power system for large scale data center, production lines in manufacturing, etc.

*Customized design is available to meet customers' demands according to user's special environment requirements.