| 绿牌潜泵技术参数 |

| 型号 | 电源 | 额定功率

(HP) | 额定电流

(A) | 堵转电流

(A) | 额定流量

(L/min) | 额定扬程

(m) | 泵体长度

(mm) |

| 标准型单相潜泵 |

| YQYBD-100-15-0.75 | 220/单相/50HZ | 1 | 5.5 | 20 | 100 | 15 | 502 |

| YQYBD-160-20-1.1 | 220/单相/50HZ | 1.5 | 8 | 27 | 160 | 20 | 578 |

| YQYBD-180-20-1.5 | 220/单相/50HZ | 1.5 | 8 | 27 | 180 | 20 | 603 |

| 标准型三相潜泵 |

| YQYB-100-15-0.75 | 380/三相/50HZ | 1 | 2.2 | 11 | 100 | 15 | 492 |

| YQYB-160-20-1.1 | 380/三相/50HZ | 1.5 | 3.2 | 21 | 160 | 20 | 578 |

| YQYB-180-20-1.5 | 380/三相/50HZ | 2 | 4 | 21 | 180 | 20 | 603 |

| YQYB-200-24-1.5 | 380/三相/50HZ | 2 | 4 | 21 | 200 | 24 | 630 |

| 高扬程潜泵 |

| YQYB-180-35-2.2 | 380/三相/50HZ | 3 | 4.8 | 26 | 180 | 35 | 944 |

| YQYB-180-45-3 | 380/三相/50HZ | 4 | 7 | 40 | 180 | 45 | 1131 |

| YQYB-180-74-4 | 380/三相/50HZ | 5.5 | 9 | 52 | 180 | 74 | 1336 |

| YQYB-200-30-2.2 | 380/三相/50HZ | 3 | 4.8 | 26 | 200 | 30 | 720 |

| YQYB-200-41-3 | 380/三相/50HZ | 4 | 7 | 40 | 200 | 41 | 1130 |

| YQYB-200-52-4 | 380/三相/50HZ | 5.5 | 9 | 52 | 200 | 52 | 1283 |

| 大流量潜泵 |

| YQYB-500-5.5-0.75 | 380/三相/50HZ | 1 | 2.2 | 11 | 500 | 5.5 | 690 |

| YQYB-500-11-1.5 | 380/三相/50HZ | 2 | 4 | 21 | 500 | 11 | 840 |

| YQYB-500-16-2.2 | 380/三相/50HZ | 3 | 4.8 | 26 | 500 | 16 | 980 |

| YQYB-500-22-3 | 380/三相/50HZ | 4 | 7 | 40 | 500 | 22 | 1200 |

| YQYB-500-34-4 | 380/三相/50HZ | 5.5 | 9 | 52 | 500 | 34 | 1220 |

| YQYB-500-46-5.5 | 380/三相/50HZ | 7.5 | 13 | 74 | 500 | 46 | 1520 |

| YQYB-500-65-7.5 | 380/三相/50HZ | 10 | 18 | 108 | 500 | 65 | 1850 |

| 大流量潜泵 |

| YQYB-650-6-1.1 | 380/三相/50HZ | 1.5 | 3.2 | 21 | 650 | 6 | 740 |

| YQYB-650-12-2.2 | 380/三相/50HZ | 3 | 4.8 | 26 | 650 | 12 | 890 |

| YQYB-650-18-3 | 380/三相/50HZ | 4 | 7 | 40 | 650 | 18 | 1100 |

| YQYB-650-24-4 | 380/三相/50HZ | 5.5 | 9 | 52 | 650 | 24 | 1040 |

| YQYB-650-34-5.5 | 380/三相/50HZ | 7.5 | 13 | 74 | 650 | 34 | 1330 |

| YQYB-650-46-7.5 | 380/三相/50HZ | 10 | 18 | 108 | 650 | 46 | 1570 |

| 大流量潜泵 |

| YQYB-800-6-1.5 | 380/三相/50HZ | 2 | 4 | 21 | 800 | 6 | 740 |

| YQYB-800-12-3 | 380/三相/50HZ | 4 | 7 | 40 | 800 | 12 | 1000 |

| YQYB-800-18-4 | 380/三相/50HZ | 5.5 | 9 | 52 | 800 | 18 | 970 |

| YQYB-800-24-5.5 | 380/三相/50HZ | 7.5 | 13 | 74 | 800 | 24 | 1190 |

| YQYB-800-32-7.5 | 380/三相/50HZ | 10 | 18 | 108 | 800 | 32 | 1350 |

| YQYB-800-38-9.2 | 380/三相/50HZ | 12.5 | 21 | 126 | 800 | 38 | 1460 |

| 大流量潜泵 |

| YQYB-1000-6-2.2 | 380/三相/50HZ | 3 | 4.8 | 26 | 1000 | 6 | 780 |

| YQYB-1000-14-4 | 380/三相/50HZ | 5.5 | 13 | 74 | 1000 | 14 | 870 |

| YQYB-1000-21-6 | 380/三相/50HZ | 8 | 14 | 83 | 1000 | 21 | 1090 |

| YQYB-1000-28-7.5 | 380/三相/50HZ | 10 | 18 | 108 | 1000 | 28 | 1248 |

| YQYB-1000-35-9.2 | 380/三相/50HZ | 12.5 | 21 | 126 | 1000 | 35 | 1380 |

| YQYB-1000-42-11 | 380/三相/50HZ | 15 | 25 | 150 | 1000 | 42 | 1570 |

| 大流量潜泵 |

| YQYB-1300-7-3 | 380/三相/50HZ | 4 | 7 | 40 | 1300 | 7 | 750 |

| YQYB-1300-14-5.5 | 380/三相/50HZ | 7.5 | 13 | 74 | 1300 | 14 | 970 |

| YQYB-1300-21-9.2 | 380/三相/50HZ | 12.5 | 21 | 126 | 1300 | 21 | 1120 |

| YQYB-1300-28-11 | 380/三相/50HZ | 15 | 25 | 150 | 1300 | 28 | 1300 |

| YQYB-1300-35-15 | 380/三相/50HZ | 20 | 34 | 204 | 1300 | 35 | 1500 |

| 大流量潜泵 |

| YQYB-2100-17-9.2 | 380/三相/50HZ | 12.5 | 21 | 126 | 1300 | 17 | 1200 |

| YQYB-2100-27-15 | 380/三相/50HZ | 20 | 34 | 204 | 1300 | 27 | 1510 |

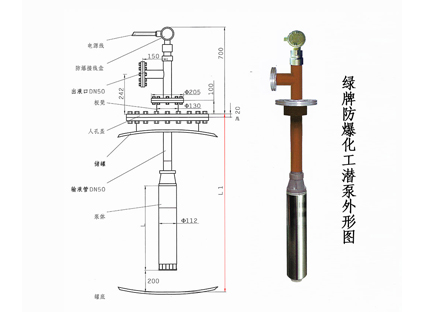

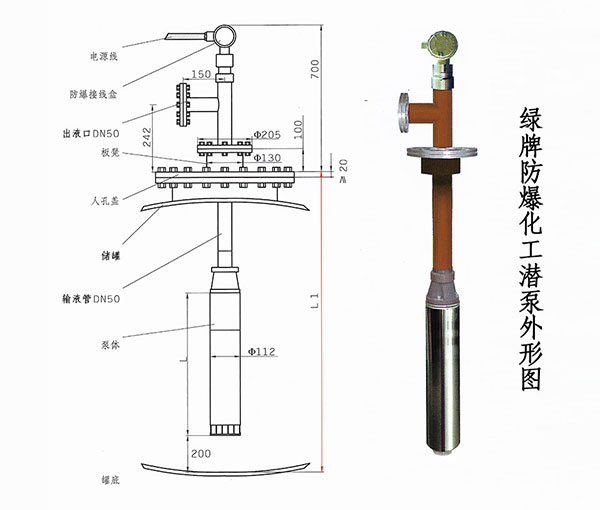

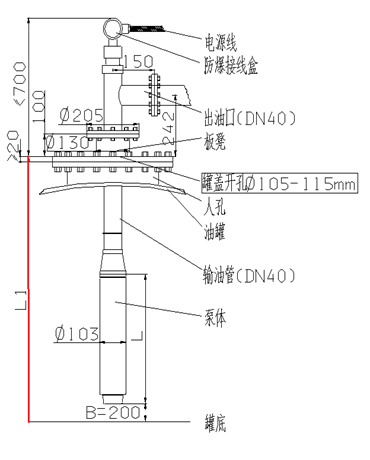

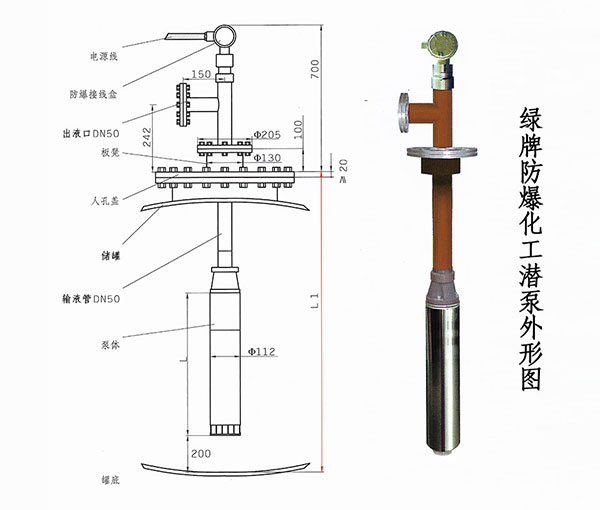

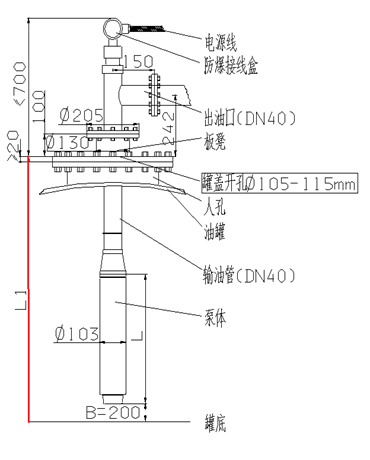

绿牌潜泵外形安装图:

1、出液口DN40到DN100不等根据客户需求定制。

2、泵体外径Φ103到185不等。

3、泵长度L1可达3-6米,可根据客户需求定制。

绿牌潜泵安装要求:

1、人孔盖厚度大于或等于20mm。

2、必须使用液位仪并与潜泵联动,如不安装,由于液位过低,冷却循环失效而造成潜泵电机温升过高而烧毁或损坏。

3、控制箱需加电机保护器。

绿牌潜泵装配顺序:

1、用吊车将泵吊起缓慢的放入人孔盖内并调整角度。

2、将潜泵的板凳与人孔盖焊接在一起。

适用介质 (不断增加中……)

脂类:

正丙酯 | 丙烯酸乙酯 |

丁内酯 | 丙烯酸甲酯 |

乙酸甲酯 | 氰乙酸甲酯 |

乙酸乙酯 | 丙烯酸异辛酯 |

乙酸丙酯 | 乙酰乙酸甲酯 |

乙酸丁酯 | 丙二酸二甲酯 |

醋酸甲酯 | 硫酸二甲酯97% |

醋酸丁酯 | 乙酸异丙酯99% |

二价酸酯 | 醋酸(乙酸)乙酯 |

丙酸甲酯 | 丙烯酸(正)丁酯 |

丙酸乙酯 | 乙二醇丁醚醋酸酯 |

丙酸丙脂 | 醋酸(乙酸)正丁酯 |

油酸甲酯 | 醋酸(乙酸)仲丁酯 |

2-羟基乙酯 | 2-乙酰基-y丁内酯 |

2-羟基丙酯 | 邻苯二甲酸二乙酯 |

水杨酸甲酯 | 乙二醇乙醚乙酸酯 |

碳酸二甲酯 | 丙二醇甲醚醋酸酯 |

(乙酸)醋酸 | 四氢呋喃+乙酸乙酯 |

乙酸叔丁酯 | 甲基丙烯酸a-羟基丙酯 |

乙酸正丙酯 | 甲基丙烯酸a-羟基乙酯 |

醋酸仲丁酯 | 甲基丙烯酸甲酯(甲甲酯) |

醇类:

戊醇 | 环己醇 |

糖醇 | 2-辛醇 |

苄醇 | 丙二醇 |

乙二醇 | (正)丙醇 |

丙二醇 | (正)辛醇 |

2-辛醇 | (正)丁醇 |

仲辛醇 | (正)已醇 |

异戊醇 | 混合戊醇 |

废乙醇 | 二乙二醇 |

二甘醇 | 二丙酮醇 |

异丙醇 | 甲醇钠甲醇溶液 |

异丁醇 | 二甘醇(二乙二醇) |

环乙醇 | 甲醇、乙醇及混合物 |

正丙醇 | 甲缩醛(甲缩醛二乙醇) |

苯类:

粗苯 | 100#芳烃 |

甲苯 | 150#芳烃 |

氟苯 | 邻二甲苯 |

硝基苯 | 邻二氯苯 |

三甲苯 | 均三甲苯 |

二甲苯 | 对氟甲苯 |

氯代苯 | 二氯苯98% |

氯化苯 | (对)二甲苯 |

苯乙烯 | 氯化苯(氯苯) |

重芳烃 | 三甲苯(S100) |

乙基苯(乙苯) |

醚类:

石油醚 | 丙二醇甲醚 |

四氢呋喃 | 甲基叔丁基醚 |

乙二醇乙醚 | 乙二醇甲醚99% |

乙二醇丁醚 | 二乙二醇单丁醚 |

烷类:

吗啉 | 环氧氯丙烷 |

正庚烷 | 甲基环已烷 |

正己烷 | 环己烷99.5% |

二氯甲烷 | 1.2-二氯丙烷 |

环氧丙烷 | 1.2-二氯乙烷 |

二乙氧基甲烷 |

胺和腈:

苯胺 | 一乙醇胺 |

乙腈 | 车用尿素 |

丙烯腈 | 甲酰胺99% |

废乙腈 | 2-氯内烯腈 |

异丙胺 | 二甲基甲酰胺 |

一甲胺 | 2,3-二甲基苯胺 |

三乙胺 | 2,6二异丙基苯胺 |

环已胺 | 二甲胺40%水溶液 |

有机酸:

正丁酸 | 醋酸(乙酸) |

异丁酸 | 甲基丙烯酸 |

丙烯酸 | NN-二甲基甲酰酸 |

乙酸36% | 冰乙酸(冰酷酸)99.5% |

环己甲酸(35℃以上可以用) |

酮类:

醛和烯:

甲醛 | 甲醛溶液 |

甲缩醛 | 高压硫化异丁烯 |

苯乙烯 | 1.1二氯乙烯99.9% |

油类和燃料:

胺和腈

松节油 |

轮胎油 |

6#溶剂油 |

120#溶剂油 |

200#溶剂油 |

松节油废水 |

1000#溶剂油 |

其它:

废水 |

甲羟 |

尿素 |

氦水 |

吡啶 |

PMA |

水合肼 |

氯化苄 |

废酒精 |

天狗2号 |

氯化亚砜 |

30%双氧水 |

| Technical Datasheet for Green Brand Submersible Pump |

| Model |

Voltage/Phase/

Frequency |

Rated Power |

Rated Current |

Locked Rotor Current |

Rated Flow |

Rated Head |

Pump Length |

| (HP) |

(A) |

(A) |

(L/min) |

(m) |

(mm) |

| Standard One-Phase Submersible Pump |

| YQYBD-100-15-0.75 |

220/1Ph/50HZ |

1 |

5.5 |

20 |

100 |

15 |

502 |

| YQYBD-160-20-1.1 |

220/1Ph/50HZ |

1.5 |

8 |

27 |

160 |

20 |

578 |

| YQYBD-180-20-1.5 |

220/1Ph/50HZ |

1.5 |

8 |

27 |

180 |

20 |

603 |

| Standard Three-Phase Submersible Pump |

| YQYB-100-15-0.75 |

380/3Ph/50HZ |

1 |

2.2 |

11 |

100 |

15 |

492 |

| YQYB-160-20-1.1 |

380/3Ph/50HZ |

1.5 |

3.2 |

21 |

160 |

20 |

578 |

| YQYB-180-20-1.5 |

380/3Ph/50HZ |

2 |

4 |

21 |

180 |

20 |

603 |

| YQYB-200-24-1.5 |

380/3Ph/50HZ |

2 |

4 |

21 |

200 |

24 |

630 |

| High-lift Submersible Pump |

| YQYB-180-35-2.2 |

380/3Ph/50HZ |

3 |

4.8 |

26 |

180 |

35 |

944 |

| YQYB-180-45-3 |

380/3Ph/50HZ |

4 |

7 |

40 |

180 |

45 |

1131 |

| YQYB-180-74-4 |

380/3Ph/50HZ |

5.5 |

9 |

52 |

180 |

74 |

1336 |

| YQYB-200-30-2.2 |

380/3Ph/50HZ |

3 |

4.8 |

26 |

200 |

30 |

720 |

| YQYB-200-41-3 |

380/3Ph/50HZ |

4 |

7 |

40 |

200 |

41 |

1130 |

| YQYB-200-52-4 |

380/3Ph/50HZ |

5.5 |

9 |

52 |

200 |

52 |

1283 |

| Large-flow Submersible Pump |

| YQYB-500-5.5-0.75 |

380/3Ph/50HZ |

1 |

2.2 |

11 |

500 |

5.5 |

690 |

| YQYB-500-11-1.5 |

380/3Ph/50HZ |

2 |

4 |

21 |

500 |

11 |

840 |

| YQYB-500-16-2.2 |

380/3Ph/50HZ |

3 |

4.8 |

26 |

500 |

16 |

980 |

| YQYB-500-22-3 |

380/3Ph/50HZ |

4 |

7 |

40 |

500 |

22 |

1200 |

| YQYB-500-34-4 |

380/3Ph/50HZ |

5.5 |

9 |

52 |

500 |

34 |

1220 |

| YQYB-500-46-5.5 |

380/3Ph/50HZ |

7.5 |

13 |

74 |

500 |

46 |

1520 |

| YQYB-500-65-7.5 |

380/3Ph/50HZ |

10 |

18 |

108 |

500 |

65 |

1850 |

| Large-flow Submersible Pump |

| YQYB-650-6-1.1 |

380/3Ph/50HZ |

1.5 |

3.2 |

21 |

650 |

6 |

740 |

| YQYB-650-12-2.2 |

380/3Ph/50HZ |

3 |

4.8 |

26 |

650 |

12 |

890 |

| YQYB-650-18-3 |

380/3Ph/50HZ |

4 |

7 |

40 |

650 |

18 |

1100 |

| YQYB-650-24-4 |

380/3Ph/50HZ |

5.5 |

9 |

52 |

650 |

24 |

1040 |

| YQYB-650-34-5.5 |

380/3Ph/50HZ |

7.5 |

13 |

74 |

650 |

34 |

1330 |

| YQYB-650-46-7.5 |

380/3Ph/50HZ |

10 |

18 |

108 |

650 |

46 |

1570 |

| Large-flow Submersible Pump |

| YQYB-800-6-1.5 |

380/3Ph/50HZ |

2 |

4 |

21 |

800 |

6 |

740 |

| YQYB-800-12-3 |

380/3Ph/50HZ |

4 |

7 |

40 |

800 |

12 |

1000 |

| YQYB-800-18-4 |

380/3Ph/50HZ |

5.5 |

9 |

52 |

800 |

18 |

970 |

| YQYB-800-24-5.5 |

380/3Ph/50HZ |

7.5 |

13 |

74 |

800 |

24 |

1190 |

| YQYB-800-32-7.5 |

380/3Ph/50HZ |

10 |

18 |

108 |

800 |

32 |

1350 |

| YQYB-800-38-9.2 |

380/3Ph/50HZ |

12.5 |

21 |

126 |

800 |

38 |

1460 |

| Large-flow Submersible Pump |

| YQYB-1000-6-2.2 |

380/3Ph/50HZ |

3 |

4.8 |

26 |

1000 |

6 |

780 |

| YQYB-1000-14-4 |

380/3Ph/50HZ |

5.5 |

13 |

74 |

1000 |

14 |

870 |

| YQYB-1000-21-6 |

380/3Ph/50HZ |

8 |

14 |

83 |

1000 |

21 |

1090 |

| YQYB-1000-28-7.5 |

380/3Ph/50HZ |

10 |

18 |

108 |

1000 |

28 |

1248 |

| YQYB-1000-35-9.2 |

380/3Ph/50HZ |

12.5 |

21 |

126 |

1000 |

35 |

1380 |

| YQYB-1000-42-11 |

380/3Ph/50HZ |

15 |

25 |

150 |

1000 |

42 |

1570 |

| Large-flow Submersible Pump+A75 |

| YQYB-1300-7-3 |

380/3Ph/50HZ |

4 |

7 |

40 |

1300 |

7 |

750 |

| YQYB-1300-14-5.5 |

380/3Ph/50HZ |

7.5 |

13 |

74 |

1300 |

14 |

970 |

| YQYB-1300-21-9.2 |

380/3Ph/50HZ |

12.5 |

21 |

126 |

1300 |

21 |

1120 |

| YQYB-1300-28-11 |

380/3Ph/50HZ |

15 |

25 |

150 |

1300 |

28 |

1300 |

| YQYB-1300-35-15 |

380/3Ph/50HZ |

20 |

34 |

204 |

1300 |

35 |

1500 |

| Large-flow Submersible Pump |

| YQYB-2100-17-9.2 |

380/3Ph/50HZ |

12.5 |

21 |

126 |

1300 |

17 |

1200 |

| YQYB-2100-27-15 |

380/3Ph/50HZ |

20 |

34 |

204 |

1300 |

27 |

1510 |

Alcohols:

1-Pentanol 、Cyclohexanol、Sugar Alchohol、Benzyl alcohol、1,2-Propanediol、Ethylene glycol、1-Octanol、D(+)-2-Octanol、1-Butanol、DL-2-Octanol、Hexyl alcohol、3-Methyl-1-butanol、Mixed isoamyl alcohol、Waste ethanol、Diethylene glycol、4-Hydroxy-4-methyl-2-pentanone、Isopropanol、2-Methyl-1-propanol、Methanol、Ethanol、Mixed methanol& ethanol、1-Propanol

Benzene Series:

Motor benzol、Aromatic Solvent Oil 100# 、Toluene、Aromatic Solvent Oil 150#、Fluorobenzene、1,2-Dimethylbenzene、Nitrobenzene、Trimethylbenzene、Mesitylene、Xylene、4-Fluorotoluene、1,4-Dimethylbenzene、Heavy aromatics、Trimethylbenzene (S100)

Ethers:

Petroleum ether、1-Methoxy-2-propanol、Tetrahydrofuran、tert-Butyl methyl ether、2-Ethoxyethanol、2-Methoxyethanol 99%、2-Butoxyethanol、Butyldiglycol

Alkanes:

Morpholine、Epichlorohydrin、Heptane、Methylcyclohexane、Hexane、Cyclohexane 99.5%、Dichloromethane、1,2-Dichloropropane、1,2-Dichloroethane、Diethoxymethane

Organic Acid:

Butyric acid、Acetic acid glacial、Isobutyric acid、Methacrylic acid、Acrylic acid、Acetic acid glacial 36%、Acetic acid glacial 99% 、Cyclohexanecarboxylic acid

Ketones:

2-Butanone、Cyclohexanone、Acetone

Amines & Nitriles:

Aniline、Ethanolamine、Acetonitrile、Diesel Exhaust Fluid、Acrylonitrile、Formamide、Waste Acetonitrile、2-Chloroacrylonitrile、Isopropylamine、N,N-Dimethylformamide、Methylamine、2,3-Dimethylaniline、Triethylamine、2,6-Diisopropylaniline、Cyclohexylamine、Dimethylamine

Aldehydes& Alkenes:

Formaldehyde Solution、Dimethoxymethane、Allyl chloride、Sulfurized isobutylene、Styrene、1,1-Dichloroethylene 99.9%

Oil and Fuel:

Diesel、gasoline、kerosene、Turpentine oil、Solvent-extracted oil #6、Solvent-extracted oil #120、Solvent-extracted oil #200、Wastewater with Turpentine oil、Solvent-extracted oil #1000

Lipid:

gamma-Butyrolactone、Methyl acetate、Ethyl acetate、Propyl acetate、Butyl acetate、DBE、Methyl propionate、Ethyl propionate、Propyl propionate、Methyl oleate、Ethyl butyrate、Methyl salicylate、Dimethyl carbonate、tert-Butyl acetate、Propyl acetate、Ethyl formate 99%、Ethyl acrylate、Methyl acrylate、Methyl cyanoacetate、2-Propenoic acid, isooctyl ester、Methyl acetoacetate、Dimethyl malonate、Dimethyl sulfate、Isopropyl acetate、Butyl acrylate、2-Butoxyethyl acetate、DL-sec-Butyl acetate、2-Acetylbutyrolactone、2-Ethoxyethyl acetate、1-Methoxy-2-propyl acetate、Tetrahydrofuran& Ethyl acetate、Vinyl acetate

Others:

Wastewater、Urea、Pyridine、Phenylmercury acetate、Hydrazine hydrate、Thionyl chloride、1,3-Dioxolane

Installation Instruction

1、Lift the pump with a crane, and put it gently into the hole on the manhole cover. Confirm the best installation position by angle adjustment.

2、Weld the riser and flange to the manhole cover.

Installation Sequence

1、The thickness of the manhole cover should be greater than or equal to 20mm.

2、A level gauge must be set and interlocked with the ESP. Otherwise, as the liquid level is too low, the cooling system would fail. The motor would be damaged with the high temperature rise.

3、A motor protector should be installed in the control box.

In China, more than 10,000 sets of Green Brand Submersible Pump were widely installed in petroleum stations, highway service areas, railway, oil depots, airports, railway trestles, piers, chemical factories, pharmaceutical factories, diesel power stations, backup power system for large scale data center, production lines in manufacturing, etc.